Undeniably one of last century’s greatest achievements was man stepping foot on the moon. And while technology continues marching forward, there is one famous icon of those lunar landings that has not yet been bested. The F-1 rocket engine is still the most powerful single chamber, liquid-fueled rocket engine ever developed. One of the engines which propelled Neil Armstrong to that famous first step, is now lovingly being restored at the Kansas Cosmosphere & Space Center.

Undeniably one of last century’s greatest achievements was man stepping foot on the moon. And while technology continues marching forward, there is one famous icon of those lunar landings that has not yet been bested. The F-1 rocket engine is still the most powerful single chamber, liquid-fueled rocket engine ever developed. One of the engines which propelled Neil Armstrong to that famous first step, is now lovingly being restored at the Kansas Cosmosphere & Space Center.

How did it get to the Cosmosphere from several miles beneath the Atlantic ocean? The first stage of the 363-foot tall Saturn V rocket contained five F-1 engines.  These were the main engines which lifted the rocket from the launch pad, starting the long journey to the moon. The first stage propelled the Saturn V for about 160 seconds, then separated from the rocket, falling back to earth, splashing down in the Atlantic Ocean some 460 miles off the Florida coast.

These were the main engines which lifted the rocket from the launch pad, starting the long journey to the moon. The first stage propelled the Saturn V for about 160 seconds, then separated from the rocket, falling back to earth, splashing down in the Atlantic Ocean some 460 miles off the Florida coast.

Although NASA calculated where these mammoth first stages would fall, no one actually knew if the first stage landed intact or broke up in flight. If the first stage broke up prior to hitting the water, the search for the engines could end up covering large sections of territory. Based upon the available data, the search team planned on covering over 100 square miles. However, depending upon the targets located and time permitting, there was certainly more area than that to search

Water depths in the search area were over 14,000 feet deep where no light penetrates. Using cameras with powerful lights could only penetrate very limited distances, and with a large search area, take years to search thoroughly. Due to the limitations of light and visual techniques, most underwater search operations utilize sonar. When talking of sonars, many people recall their use in World War II to locate submarines. The sonar transmits an acoustic pulse or ping which reflects off mid-water targets determining a range and bearing to the object. Locating relatively smaller items on the sea floor requires a different type of sonar.

The key is being able to produce acoustic imagery of the sea floor with enough resolution to locate your target while also covering as much ground as you possibly can. These bottom-imaging sonars are known as side scan sonars. These systems can create high-resolution images of the sea floor, depicting geology or targets such as shipwrecks. The same type of sonars are used by the navy to find submerged mines, for oil and gas firms to map pipelines and to help scientists map ocean bottom habitat.

The data provides overhead images of the sea floor so one can see details like the mast on a sailing ship. Unlike true photographs, the sonar images are created with sound pulses. Photographs require light which has extremely limited range underwater. The side scan sonar can cover hundreds of meters of bottom in a single pass.The sonar is deployed from a long cable on a torpedo-shaped sensor called a towfish or carried by an independent robot submarine called an autonomous underwater vehicle (AUV). Two transducers on either side of the towfish send and received acoustic pings, producing two sets of bottom imagery one for each scanned side. Thus the side scan moniker.

The data provides overhead images of the sea floor so one can see details like the mast on a sailing ship. Unlike true photographs, the sonar images are created with sound pulses. Photographs require light which has extremely limited range underwater. The side scan sonar can cover hundreds of meters of bottom in a single pass.The sonar is deployed from a long cable on a torpedo-shaped sensor called a towfish or carried by an independent robot submarine called an autonomous underwater vehicle (AUV). Two transducers on either side of the towfish send and received acoustic pings, producing two sets of bottom imagery one for each scanned side. Thus the side scan moniker.

One limitation of side scan is range verses resolution. The F-1 rocket engines were scattered over hundreds of square miles. The search team needed to cover large swaths of sea floor with each pass of the sonar. Due to the physics of sound in water, the longer the range, the poorer the resolution of sonar. At short ranges, side scan will image small, hard-to-detect objects such as drowning victims. At long ranges, only larger or highly reflective targets such as metal debris are visible. So scaning out over 1000 meters (all sonar ranges use scientific metric units: 1 meter = 3.28 feet) per side, the capability to detect objects is still very good, however, the definition is not as great. We can see targets but only experienced operators can interpret the imagery, and even then, it is part learned art and part science.

Science, however, has provided a new synthetic aperture sonar (SAS) which does not lose resolution at long ranges.

The new sonar can see targets at over 1000 meters with a resolution of a few inches. That’s that is the equivalent of seeing something as small as an aircraft propeller at a distance of 10 football fields or more. The team brought both conventional side scan and SAS systems with them on the expedition, since the new SAS had not yet been fully tested.

Both the SAS and the conventional side scan sonar work by towing the sonar close to the sea floor from a long cable. The acoustic signals are transmitted up the cable to a computer onboard the ship which displays real-time images of the sea floor. The sonar’s position is integrated into the data, and operators click on the imagery to determine target position, size and height above bottom. Equipment robust enough to survive the deep ocean and transmit data back to the ship over several miles of cable is large and expensive.

The new SAS system cost over a million dollars to build. The towfish was over 15 feet long and weighed six tons. It also required 10,000 meters or 32,800 feet of wire to get the towfish close enough to the sea floor over two miles below the ship. That spool of cable alone weighed in at over 20 tons. Additionally, there is a large hydraulic power until which powers the cable winch. The equipment is run by a team of search specialists who travel with the equipment and are separate from the ship’s crew. Once on station, the search team will work 24 hours per day, seven days a week until the job is completed. All the search equipment and extra crew required a large ocean-going ship over 200 feet long with a large A-Frame on the stern. The A-frame supports a large wheel called a sheave over which the cable rolls into the ocean. The sheave automatically measures the length of cable deployed to assist with calculations of towfish position.

The search team met the ship in Norfolk, Virginia where all the search equipment was offloaded from several 18 wheeler trucks onto the vessel. The winch with cable and the hydraulic power unit had to be lifted by crane, placed onboard and welded to the deck. The towfish, computers and special navigation systems where loaded onboard as well. All the systems were assembled and tested prior to leaving the dock. When all the equipment was ready, the ship departed Norfolk on her way south east to the search area.

The search team met the ship in Norfolk, Virginia where all the search equipment was offloaded from several 18 wheeler trucks onto the vessel. The winch with cable and the hydraulic power unit had to be lifted by crane, placed onboard and welded to the deck. The towfish, computers and special navigation systems where loaded onboard as well. All the systems were assembled and tested prior to leaving the dock. When all the equipment was ready, the ship departed Norfolk on her way south east to the search area.

Hurricane season officially starts in the Western Atlantic ocean June 1st and lasts through November 30th. Ocean commerce does not stop during the season, but vessels do keep an eye on the weather. Hurricanes were moving up the central Atlantic but luckily did not approach the search area. The survey ship hugged the coast while transiting to avoid the large waves created by hurricanes hundreds of miles away.

As the seas settled, the ship reached the search area and the team launched the SAS towfish. Deploying a deepwater sonar towfish to the bottom is a long, tedious process that takes over five hours. This was the first deepwater deployment of the SAS system, and the images relayed back up the fiber optic cable were outstanding! The detailed images vividly displayed sand ridges and furrows in definition that previously had not been seen with deepwater acoustic imagery. But the team’s elation was quickly replaced with frustration as the four large computer monitors went dark. While the technology had proven itself, there was a problem with the fiber optic lines in the cable.

The team recovered the towfish and quickly swapped the SAS with the older side scan sonar. This low-frequency, long-range system covered the same 1200 meters per side, however with significantly less resolution. The first survey line was over 30 nautical miles long, and for seven days round the clock, the team scanned the ocean bottom, covering over 180 square miles of sea floor. Every target position was plotted and matched with flight trajectories of multiple Apollo missions. The debris seemed to correlate with NASA’s calculated positions although the data points appeared further down-range than had been expected. After mapping over 180 square miles of sea floor, the team had located 18 concentrations of debris with hundreds of pieces of debris scattered in between.

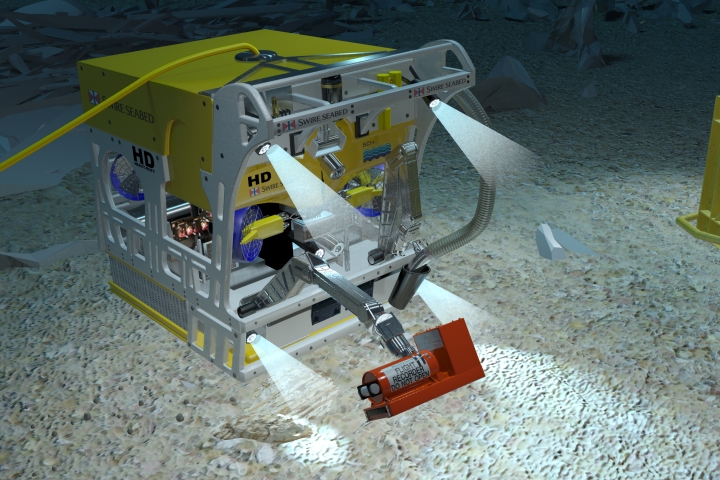

Back onshore the team poured over the data for months, calculating which debris fields represented debris from different Apollo missions. The ultimate goal was to recover F-1 engines from Apollo 11, the first mission to land men on the moon. Since deploying deepwater robots to the debris fields is a time-consuming process, the goal was to place the robots on the debris most likely from the Apollo 11 mission. Once on the bottom, the robots could not travel miles to the next location without being first recovered to the ship; each time that would take four to six hours. The completed analysis seemed to point to three debris fields in close proximity which aligned with the Apollo 11 flight azimuth. With that data in hand, the green light was given for Phase II: recovery of the F-1 engines.

Phase II commenced by finding a ship equipped with deep-ocean robots which could handle the recovery. Join us for our next post examining the ship and robots needed to lift a nine-ton object from over two miles beneath the ocean.

© Copyright Vince Capone 2013

Printed with permission from Bezos Expeditions.

Missed earlier posts in this series?

The story begins here: How Do you Recover An Apollo Rocket Engine from 3 Miles Beneath the Bermuda Triangle?