The recovery team arrived in Bermuda a few days ahead of the ship. The hours were filled with dozens of logistical items requiring attention, including the storage of spare equipment, last minute loading of fresh food and numerous planning sessions. Team leaders met to finalize plans for operations aboard the ship.

The Seabed Worker would stay in Bermuda less than eight hours and the transition had to flow smoothly to ensure a timely departure. Transit to the recovery site would take just over 30 hours, and our final destination would put us approximately mid-way between Bermuda and Cape Canaveral, Florida.

The recovery area was strewn with wreckage from over half a dozen Apollo missions. Each first stage mounted five F-1 engines. Our goal was to find and recover one or more F-1 engines from the massive first stage of Apollo 11, man’s first flight to the lunar surface.

There were 18 concentrations of debris with engine-like sonar contacts. The team plotted flight azimuths and calculated splashdown locations of each mission to correlate debris fields with specific Apollo missions. During the transit to the recovery location, the team refined the recovery plan.

The ROV pilots serviced vehicles and charged acoustic navigation beacons. Team members prepared systems, charged batteries, recalculated locations and tested the 600 terabyte data storage system.

After 32 hours, the ship was finally holding position over the highest priority debris field. Everyone anxiously awaited the order to dive the vehicles. However, this highly-sophisticated operation required numerous interlocking systems, any of which could fail, endangering a seven-million-dollar robot or worse, a team member.

So prior to the first dive, the ship executed a series of dynamic positioning tests to ensure the vessel would hold position during the recovery. The ROV team ran each robot through a series of checks and the entire team participated in a mandatory pre-launch safety meeting. Every aspect of the operation, including where the team was allowed on deck during operations, was painstakingly detailed. While we did have a expedition doctor on board, a serious injury would require the vessel to recover the robots and run for port as we were too far at sea to be reached by helicopter.

The ship rolled in a long period swell while nicely holding position over our primary debris field. The weather forecast predicted workable weather for the next 24 to 36 hours. The order was given to splash the first robot which commenced the almost four–hour descent to the bottom. Once started, operations would be continuous, rotating teams round the clock, seven days a week until the weather forced us to take a break.

The original search operation had been conducted with a towed sonar deployed with over five miles of cable. The long tow cable reduced the target accuracy, meaning the ROVs could not set down exactly on our targets. The pilots would fly search patterns scanning ahead with forward-looking sonar to find each contact.

On paper, the target clusters looked small, but in reality, there were often dozens of meters between pieces of debris. Ridges and furrows covered the bottom, hiding targets and requiring more searching to ensure no contacts lie hidden behind a ridge or in a furrow.

Acoustic beacons mounted on the top of the ROV provided underwater positioning and tracking. Based upon the range and bearing from the ship to the beacon, we could determine the approximate vehicle position. Tracking the ROVs and coordinating the ship’s position with the robots on the bottom was the job of the navigator. The navigator’s information was broadcast via Ethernet throughout the ship so everyone from the captain to the ROV pilots could visually track the robots’ progress across the bottom.

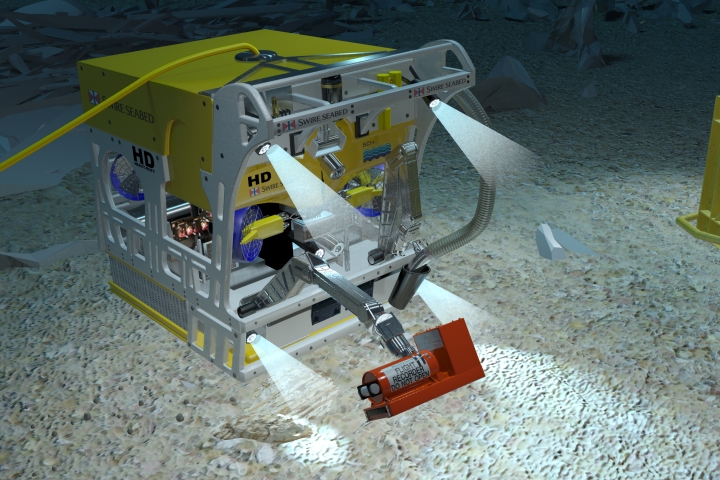

The ROV with the camera called HD23 was launched through a large opening in the ship called a moon pool. A very large four-storey A-frame handling system elevated HD23 off the deck and a large sliding section of deck slowly exposed the open sea in the moon pool. The ROV and handling system then descended through the moon pool into the surging sea below, where the ROV detached from the handling system and began its decent to the bottom. Four hours later, the ROV arrived on the sea floor some two and half miles beneath the ship.

The second ROV, HD28 with the hydraulic dredger, was launched from a hanger door on the port side of the ship with an A-frame that extended out over the water. Each robot had two pilots who sat in comfortable high-backed seats with a joystick in each hand and a dozen computer screens to monitor. The bank of computer displays provided each pilot team with a view from multiple cameras showing the ROV position relative to targets, scanning  sonar and winch information. In addition to the flight controls, each pilot had a touch screen where he accessed vehicle sub-menus such as hydraulic pumps and monitoring information which continuously provided the status of the ROV’s sub systems.

sonar and winch information. In addition to the flight controls, each pilot had a touch screen where he accessed vehicle sub-menus such as hydraulic pumps and monitoring information which continuously provided the status of the ROV’s sub systems.

HD23 searched for the targets. Once the targets had been located, we deployed HD28, the second ROV with the dredge, and started to dig out around the engines, looking for serial numbers and other identification information. We had many targets on the bottom since the engines had broken away from the thrust structure and were more scattered than we had expected.

The archaeologist and recovery team sat in front of multiple large screen TVs showing high-definition pictures.

The archaeologist and recovery team sat in front of multiple large screen TVs showing high-definition pictures.

Each piece of debris on the screen was logged with the date and video time code. The sonar specialist would cross reference targets in the video with the sonar data collected during the search operation. Additionally, the operations manager continuously coordinated with all the teams, pilots, navigator, archaeologist, and ship’s crew to ensure an efficient process. As each piece of debris was located and catalogued, the team updated navigation plots and sketched out the best course of action for the ROV.

Once the ROVs hit the water, the recovery team started round-the-clock operations and never stopped except for weather. The cooks worked seemingly continuously preparing meals and keeping the coffee machine full. The 24-hour galley was a godsend, especially for those working the night shift.

Generally the recovery team worked in 12-hour shifts, with shift changes occurring either at noon/midnight or 6am/6 pm. The shift changes matched meal times, allowing those going on or coming off shift to grab a meal. There were four meals a day. In addition to the standard breakfast, lunch and dinner, the fourth meal known as mid-rats, short for midnight rations, was usually left over from lunch and dinner. Snacks were available around the clock and special dinners were served on weekends. While the 12-hour days sound fairly civil, the reality was different for many of the team members. If the ROVs broke down or there was a recovery of artifacts or there were meetings which required folks to be present, sleep was second to everything else. On good nights, there was six hours of uninterrupted sleep, while most times the team worked on less. As every shift ended, there would be a hand-off meeting so the next shift would know exactly where to take over.

Generally the recovery team worked in 12-hour shifts, with shift changes occurring either at noon/midnight or 6am/6 pm. The shift changes matched meal times, allowing those going on or coming off shift to grab a meal. There were four meals a day. In addition to the standard breakfast, lunch and dinner, the fourth meal known as mid-rats, short for midnight rations, was usually left over from lunch and dinner. Snacks were available around the clock and special dinners were served on weekends. While the 12-hour days sound fairly civil, the reality was different for many of the team members. If the ROVs broke down or there was a recovery of artifacts or there were meetings which required folks to be present, sleep was second to everything else. On good nights, there was six hours of uninterrupted sleep, while most times the team worked on less. As every shift ended, there would be a hand-off meeting so the next shift would know exactly where to take over.

An operation really revolves around meals and is a great morale booster, especially when the food is excellent, which it was on this mission. When you’re working most of the time, you loose track of time. Only the meal schedule lends itself to normalcy. In off-time, the team could do their laundry, workout in the ship’s gym or watch Satellite TV in the lounge. Occasionally, we could email back to shore. There were two men to each cabin with its own head (bathroom). Everything was bolted down so when the weather kicked up, furniture would not slide across the deck.

We had catalogued 18 concentrations of debris with engine-like sonar contacts covering over 40 square miles of ocean. We had conducted an analysis and felt that there were three areas that had the highest probability of containing the remains of Apollo 11. With the vessel in position, we launched the ROVs and waited through the agonizingly-long descent.

“Bottom in sight” came over the radio net. HD23 had reached the sea floor, ready to commence the search for Apollo 11. HD23 had just arrived at our highest priority search area. After all systems were given a check, the team started the ROV running a search pattern to locate the debris found by the search sonar.

“Contact. Target at 2 o’clock. Range 30 meters,” stated the operations manager and the ROV swung right to investigate. The recovery team focused on the big screen, watching as the sea floor passed underneath the vehicle. The tension was broken by another call, this time from the pilot. “Lost it.” The contact had disappeared from the forward-looking sonar. The ROV had followed the bottom into a furrow and there was a small rise between the ROV and the target. Slowly the ROV climbed to the top of the ridge and the target reappeared on the sonar screen. There was a collective sigh of relief as the vehicle closed in on the target. Smaller contacts now showed on the sonar screen. We had found the first debris field.

No one was 100 percent certain what we would find. Experts had told us the first stage had hit the water intact and the debris fields should be fairly localized. However, there were accounts from passing ships that told of debris falling long distances from the calculated impact zones. The view on the bottom confirmed the ship reports, as the remains were widely scattered.

The second confounding factor was there were over a half dozen space missions that dropped debris in the same area, and we were specifically looking for the engines from Apollo 11. The ROV passed over a small piece of fuel line as the larger sonar target slowly took shape.

What appeared on the screen did not at first look like a F-1 rocket engine. However, as the vehicle circled the target, we were confident we had indeed found the main thrust chamber of an F1 engine.

The forces of re-entry and impact with the ocean had stripped this massive engine of the turbo pump, gimbal bearing, liquid oxygen dome and injector, gas generator and heat exchanger. Even the giant nozzle built to withstand the super heated exhaust gases was gone.

Was this an engine from Apollo 11? The ROV with its super high-resolution camera moved in for a closer look. And after a careful examination, we could not find any identifying serial numbers, so we decided to continue our examination of the debris field in hopes of finding another engine in better condition.

Join us in our next post as we continue our operations trying to locate an engine in better condition with a visible serial number to confirm the debris was indeed from Apollo 11.

© Copyright 2014 Vincent Capone

With Permission from Bezos Expeditions

Missed earlier posts in this series?

The story begins here: How Do you Recover An Apollo Rocket Engine from 3 Miles Beneath the Bermuda Triangle?

The search gets underway here: Finding An Apollo Rocket Engine in the Deep Ocean

The best recovery ship for the job is found here: The Right Stuff for a Deepwater Recovery